Last Updated on January 23, 2025 by Jeffrey Calderon

Road Construction Work Safety Tips

Are roadway contractors putting their lives at risk every day?

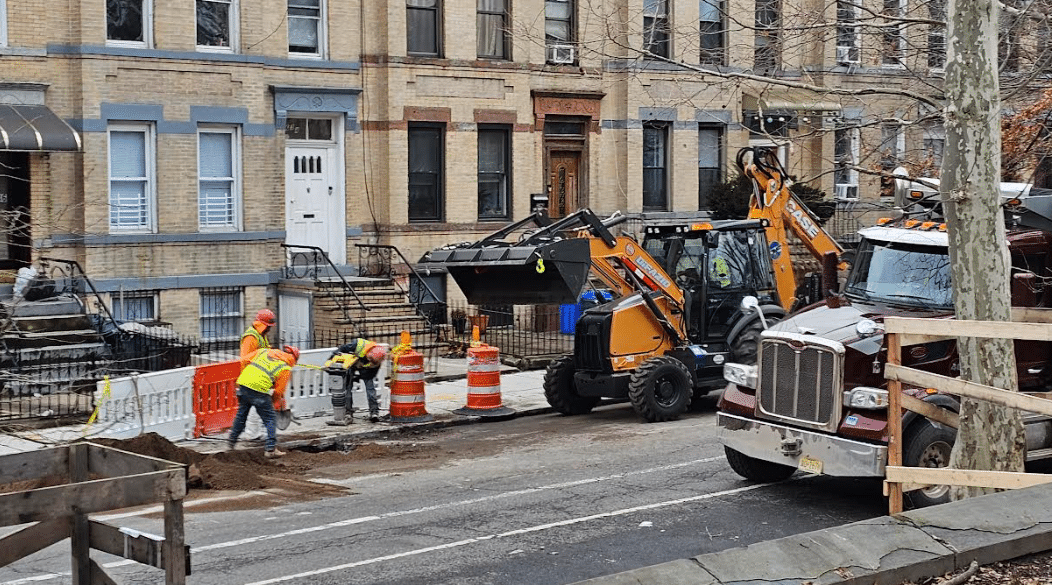

Like it or not, building our roadways comes at a great cost to our construction workers.

From 2003 to 2017, an average of 123 people were killed on road construction sites annually.

Aside from the normal dangers of construction on our city streets, our highway systems have even more perils.

Highway work zones must deal with heavier pedestrian traffic, bulky equipment, construction vehicles, and environmental hazards.

We’ve compiled the best safety practices in this blog post for roadway contractors to make it home safe and sound.

We may receive compensation through our affiliate links below at no additional cost to you.

The Most Common Causes of Road Construction Injuries

Construction on roads brings many risks — there isn’t just the risk of dangerous equipment or collisions.

Most fatalities were either caused by workers being struck by a regular car or hit by moving construction equipment or vehicles from 2007 to 2010.

Ongoing safety training can help contractors improve workplace safety and adhere to work zone safety precautions.

Other commonly cited roadway injuries include slip/fall injuries, overexertion, and toxic substances.

Knowing construction safety statistics can bring awareness to how dangerous certain construction activities can be.

Although some injuries on the roadways were minor, we can’t ignore the fatal occupational injuries these workers are subjected to.

Ensure a Competent Person is On Site

A competent employee consistently looks for existing and potential hazards around the working environment that can cause injury to other construction employees.

Competent personnel can change the site to eliminate identified risks, such as idling construction vehicles, missing uniform traffic control devices, and electrical hazards.

Requiring competent workers may appear as straightforward as it sounds, but it could quickly become hazardous if your only competent worker leaves the workplace.

Find out what your key “competencies” are in your team, and implement a schedule if needed.

Implement Proper Training

The road construction industry is expected to undergo extensive training to prepare workers to understand the policies in operation and the potential risks faced.

Requiring consistent protocol across teams ensures the entire team follows the same process.

Are you performing daily inspections on worker safety procedures?

If any issues arise during these safety checks, secure the area first to avoid accidents and make a report.

Road Work Zone Safety Tips

Every element on job sites can be dangerous when employees do not understand what equipment they need and how to operate it safely.

Safety advice for road builders and other administrative activities is here to ensure a safer workplace.

Slow Down and Follow Posted Speed Limits:

When approaching a road work zone, reduce your speed and adhere to posted speed limits.

Speeding in construction areas increases the risk of accidents and endangers workers and drivers.

Stay Alert and Avoid Distractions:

Pay close attention to road signs, flaggers, and construction signals.

Avoid distractions such as texting, talking on the phone, or adjusting electronic devices while driving through work zones.

Keep a Safe Following Distance:

Maintain a safe following distance from the vehicle in front of you.

Construction zones may require sudden stops or lane changes, and having adequate space helps prevent rear-end collisions.

Obey Traffic Control Devices:

Follow instructions from flaggers and obey all traffic control devices, including cones, barricades, VMS boards, and signs.

Be prepared to merge or change lanes as directed by construction personnel or signage.

Be Mindful of Construction Workers:

Watch for construction workers, dump trucks, and other equipment in the work zone.

Yield the right-of-way to workers and equipment, and be patient as they perform their tasks to enhance overall safety in the construction area.

Increase Worker and Work Site Visibility

OSHA requires contractors working on highways to wear high-visibility clothing.

High-visibility clothing includes hats, pants, and wristbands made of reflective or fluorescent materials.

You could use light to boost visible areas during the night or during times of difficulty.

Worker Safety for Highway Construction Standard

A10.47-2009: Work Zone Security for Road Construction is now in force.

The policy applies to highway workers involved in the construction work zone, utility work, and maintenance of a roadway.

The book includes procedures such as:

Flagger Safety Runover

Flagger safety is a critical concern in roadway construction zones, and the risk of runovers poses a significant challenge.

Flagger Safety Runover refers to the dangers faced by flaggers responsible for managing traffic flow through construction areas.

These professionals play a crucial role in ensuring the safety of both workers and motorists. To mitigate the risk of runovers, flaggers must be equipped with high-visibility safety apparel and proper signaling tools.

Additionally, establishing clear communication protocols among the construction crew, providing adequate training, and implementing effective traffic control measures are imperative.

Drivers approaching construction zones should remain vigilant, adhere to posted speed limits, and be prepared to follow flaggers’ instructions promptly to prevent potential accidents and ensure the overall safety of the construction site.

Back Over Prevention

Back-over prevention ensures safety in various settings, particularly in construction sites, parking lots, and residential areas.

Back-over incidents occur when a vehicle, often larger ones like trucks or heavy equipment, unintentionally moves backward and strikes a person, typically in the blind spot behind the vehicle operator.

Advanced safety features like backup cameras and sensors have become increasingly common in modern vehicles to prevent such accidents.

Clear communication and worker coordination are also crucial, especially in construction zones. Establishing designated walkways, spotter assistance, and employing audible warnings contribute significantly to back-over prevention efforts.

Strict adherence to safety protocols, regular training for vehicle operators, and implementing technology-driven solutions collectively minimize the risks associated with back-over incidents, enhancing overall safety in work and public environments.

Equipment Operator Safety

Equipment operator safety is paramount in various industries, particularly in construction, manufacturing, and transportation.

Those operating heavy machinery and equipment are responsible for their safety and those around them.

Adherence to proper safety training schedules and protocols, including understanding equipment functions, safety features, and emergency procedures, is fundamental.

Equipment operators must consistently wear appropriate personal protective equipment (PPE) and follow established safety guidelines and protocols. Regular equipment maintenance checks are essential to identify and address potential issues that could compromise safety.

Operators should remain vigilant in their surroundings, communicate effectively with coworkers, and be aware of potential hazards to prevent accidents.

Emphasizing a safety culture, ongoing training, and implementing technology-driven safety measures contribute to fostering a secure environment for equipment operators and those working alongside them.

Lighting

Lighting plays a crucial role in ensuring worker safety on roadway construction sites.

Adequate illumination is essential, especially during nighttime operations or in low-light conditions, to enhance visibility for both workers and passing motorists.

Properly lit construction and highway work zones can reduce the risk of accidents, help workers navigate the area safely, and make construction activities more visible to oncoming traffic.

Bright and strategically placed lighting contributes to the identification of potential hazards, machinery, and workers, fostering a safer work environment.

In addition to preventing collisions and accidents, well-designed lighting systems facilitate efficient communication among construction crews.

Ensuring sufficient and well-distributed lighting is, therefore, a key component of road construction safety measures, promoting the overall well-being of workers and enhancing the effectiveness of road construction safety and operations on roadways.

Personal Protective Equipment

Photo Credit: Malta Dynamics

Proper Personal Protective Equipment (PPE) plays a pivotal role in ensuring the safety and well-being of workers in roadway construction. Construction sites are inherently hazardous environments, and PPE is a critical defense against potential risks.

This typically includes high-visibility clothing, hard hats, safety gloves, steel-toed boots, and eye protection for road construction workers.

High-visibility clothing, often in fluorescent colors with reflective materials, enhances visibility, reducing the likelihood of accidents involving moving vehicles.

Hard hats can protect workers against falling objects, while safety gloves shield hands from potential injuries during manual labor.

Steel-toed boots offer foot protection and eye protection safeguards against debris or other airborne hazards.

By wearing the appropriate PPE, workers comply with safety regulations and significantly reduce the risk of injuries related to their specific tasks.

PPE is a crucial safeguard, ensuring that roadway construction workers can perform their duties with heightened protection in an environment where potential hazards are prevalent.

Safety Standards for Road Construction Sites

The broader community is helping make the work area safer and the work zones more efficient.

A very important one is OSHA, which imposes a number of rules about workers’ safety activities.

Occupational Safety and Health Administration (OSH) enacted a PPE requirement.

Other key players in road safety standards are FEHWA and FEHWA.

The Manual on Uniform Traffic and Control Devices defines the various traffic control plans, devices, and procedures for almost all roadworks projects.

These guidelines describe the need for high-visibility clothing or accessories.

They all rely on guidelines from ANSI.

Final Thoughts

I can’t emphasize the importance of safeguarding yourself when working on NYC roadways and highways.

Roadway contractors are at the most risk of having a fatal injury while working.

It all boils down to having safety protocols and holding each co-worker onsite accountable for being safety conscious.

Look out for each other and report any worksite safety issues to supervisors immediately.

If you suspect a supervisor isn’t performing their own due diligence, you can report them to OSHA directly.

Construction on roadways should never cost a contractor their life; thank you for reading, and stay safe out there.

Frequently Asked Questions

Are there specific rules regarding engine idling or noise reduction in construction zones?

Some construction zones may have regulations to minimize noise and air pollution. Drivers should be aware of any restrictions on engine idling and take measures to reduce unnecessary noise when passing through these areas

What should drivers do if wildlife is disrupted by construction activities on or near the roadway?

Construction projects can sometimes disturb local wildlife. If drivers encounter animals on the road or near construction zones, it’s recommended to slow down and allow the animals to move away safely. Reporting such incidents to local authorities can also help mitigate potential risks.

Can drivers use hands-free communication devices while passing through construction zones?

Laws regarding using hands-free devices vary, but drivers must know local regulations. In some areas, even hands-free communication might be restricted in construction zones to ensure full driver attention and safety.

Why are speed limits reduced in construction zones, and how should drivers adjust their speed?

Speed limits are reduced in construction zones to enhance safety for both drivers and construction workers. Drivers should adhere to posted speed limits, slow down when approaching work zones, and be prepared for sudden stops or lane changes.